As the number of guests in our retreat program has increased in recent years, so has the volume of food scraps that our kitchen produces. For decades, our chickens, goats, garden hot heap compost piles, and vermiculture (worm) bins were sufficient for processing our kitchen compost, but as we’ve ramped up our integrated food system, it became clear that we needed to find a solution to bring the kitchen and gardens back into balance. As with any emerging challenge, we were also presented with an opportunity–not only to produce more compost, but also to demonstrate a commercial-scale sustainable food composting solution.

Introducing the Ridan Food Composter! Above, Garden Manager Michelle Krieg happily turns the composter during her daily chores.

Earlier this year, we installed a new mechanical, continuous-flow aerobic composter designed for commercial kitchens. Garden Manager Michelle Krieg had previously worked with this system in England and found it to be highly functional, pest proof, easy to manage, and reliable for processing all types of food scraps – even meat and small bones! She especially loved how its continuous-flow technology required minimal hauling and turning labor. OAEC is now one of the first demonstration sites on the West Coast to be using this highly efficient solution for food scrap recycling.

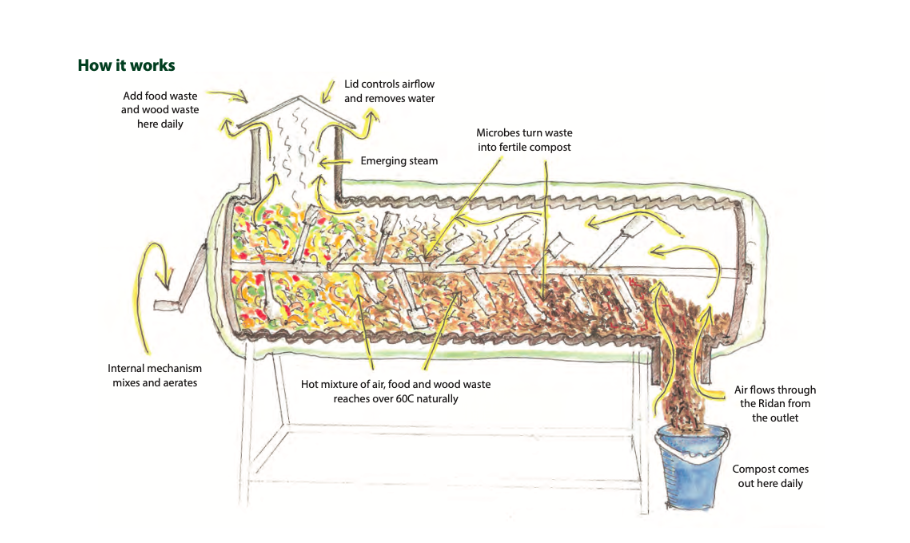

How does it work?

Each week, the OAEC garden team adds 10-20 5-gal buckets of food scraps into the composter, along with organic-approved wood pellets in a 6:1 Nitrogen-Carbon ratio. After its daily feeding, they turn the hand-crank for around three minutes to incorporate new material and also aerate any decomposing material inside the unit. It takes about 3-4 weeks for food to move through the composter, heating up to 140-160F through a natural thermophilic decomposition process. As new material is incorporated each day, fresh compost is also released through the other end of the composter, which is then stored in a maturation bin for 2-3 more months until it’s ready to use in the gardens.

Over the last four months OAEC has already processed around 4000 pounds (155 5-gal buckets) of food scraps into beautiful, fluffy compost (shown at the top of this post). The continual flow-through and constant turning of this technology has reduced the processing time from ~9 months to only 3-4 months, allowing us to not only increase the volume of food scraps we’re able process, but also accumulate more compost in bulk. This, in turn, will facilitate the Mother Garden’s transition towards a “no dig” growing approach which requires amending a thick 2″ layer of compost on our beds each year. All in all, we’ve been impressed with the results of this “revolutionary” new addition to our suite of composting options!

If you’d like to learn more about this mechanical composting technology, check out the Ridan Food Composter website at https://www.ridan.co.uk/.